Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

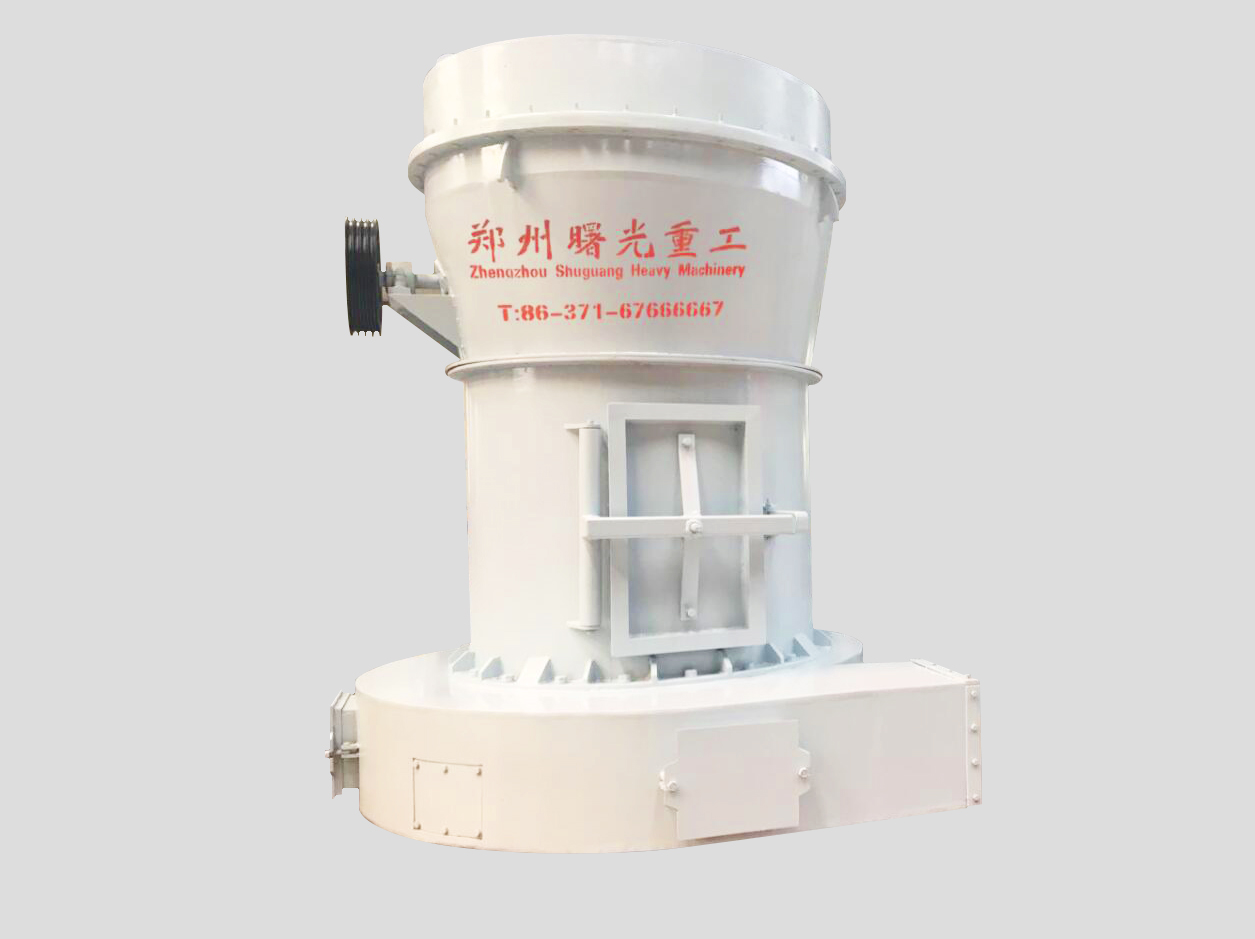

Structure of R-type Raymond Mill Zhengzhou Shuguang Heavy Machinery Co., Ltd. Production of R-type Raymond Mill is mainly by the mill mainframe, and related Equipment analyzer, cyclone separator, blower, motor, and other components, related to the ancillary equipment are: jaw crusher, hoist, details call: 0371-67666667 The working principle of Raymond Grinder Raymond Mill work will be large block of raw materials broken into the required size of the feed, from bucket elevator to the material to the storage bin, and then by the electromagnetic vibration feeder evenly sent to the grinding machine of Raymond Miller's main engine, into the grinding room of the material by shovel knife shovel into the grinding roller and grinding ring between the broken, blower air from the persion plate into the grinding room, the crushing powder is sent to the analysis room, the separation of the impeller is carried out through the driving device by the speed regulating motor, and the large granule material is returned to the grinding chamber, the grinding Fineness conforms to the specifications of the powder with the airflow into the finished Cyclone powder collector, and air separation, from the discharging port to the finished product. The blade system plays a very important role in the working process of the main machine of Raymond Mill. It is located at the bottom of the mill roll, the shovel knife and the grinding roller in the process of feeding the material shovel into the roller ring, forming a cushion layer, the material layer by the grinding roller rotation outward pressure will crush the material, thereby achieving the purpose of milling.

| model | 3R2115 | 3R2615 | 3R2715 | 3R3016 | 4R3216 | 5R4119 | ||

| Roller | Number | 3 | 3 | 3 | 3 | 4 | 5 | |

| diameter(mm) | 210 | 260 | 270 | 300 | 320 | 410 | ||

| height(mm) | 150 | 150 | 140 | 160 | 160 | 190 | ||

| mill ring | the inside diameter of(mm) | 630 | 780 | 830 | 880 | 970 | 1270 | |

| height(mm) | 150 | 150 | 140 | 160 | 160 | 190 | ||

| Maximum feed size(mm) | 15 | 15-20 | 15-20 | 15-20 | 20-25 | 20-25 | ||

| Finished grain size(mm) | 0.44-0.165 | 0.44-0.165 | 0.44-0.165 | 0.44-0.165 | 0.44-0.165 | 0.44-0.165 | ||

| monitor rate(KW) | 15 | 18.5 | 22 | 30 | 37 | 75 | ||

| Finished product Fineness(mm) | 0.125 | output(t/h) | 1.2-1.8 | 1.8-2.5 | 2.3-2.8 | 0.6-1.2 | 3.2-4.5 | 2.3-6.8 |

| 0.075 | 0.6-1.2 | 1.2-1.8 | 1.8-2.3 | 1.9-2.6 | 2.4-3.1 | 2.0-4.5 | ||

| 0.044 | 0.6-1.0 | 0.8-1.2 | 0.9-1.7 | 1-1.9 | 1.8-2.5 | 1.8-4.0 | ||