Processing Capacity:

Feeding Size:

Applied material:

Application Field:

Send E-mail:shuguang_mill@163.com

High efficiency dolomite grinding powder production line

Brief Introduction

1.Application: paint,pipe,cosmetics,plastic parts,floor etc

2.Suitable materials: gypsum,talc,calcite,limestone,marble,dolomite,iron ore,cement,granite,clay,kaolin and so on( nonflammable and non-explosive materials with humidity below 6% and Mohs hardness less than 7)

3.Feed size:≤25mm (if you material is big,please add a jaw crusher)

4.Outlet size:60-325 mesh(if you need other fineness,we also have other type mill,please contact)

5.The whole production line include:jaw crusher,elevator,hopper,feeder,raymond mill,electric cabinet etc.

6.Power:Different modes is different,please contact us and ask. copper powder making machine

Technical Parameters

| Model | 3R3015 | 3R2715 | 3R2615 | 3R2115 |

| Feedingsize(mm) | ≤25 | ≤25 | ≤20 | ≤15 |

| Finenessoffinishedproduct(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

| Production(t) | 1-4 | 0.9-3.5 | 1.7-3 | 0.5-2 |

| Speedofaxis(r/min) | 160 | 160 | 160 | 180 |

| DiaofRing(mm) | 860 | 830 | 780 | 650 |

| DiaofRoller(mm) | 300 | 270 | 260 | 210 |

| Rollerheight(mm) | 150 | 150 | 150 | 150 |

| Mainmotor(KW) | Y225m-8-22 | Y225m-8-22 | Y225s-8-18.5 | Y200L-8-15 |

| Fanmotor(KW) | Y180m-4-22 | Y160L-4-18.5 | Y160L-4-15 | Y160m-4-11 |

| Analysismotor(KW) | Y112m6-2.2 | Y112m6-2.2 | Y112m6-2.2 | Y112m6-2.2 |

| Model | 6R4525 | 5R4121 | 5R4119 | 4R3218 | 4R3216 |

| Feedingsize(mm) | ≤30 | ≤30 | ≤25 | ≤30 | ≤30 |

| Finenessoffinishedproduct(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

| Production(t) | 13-40 | 8-15 | 5-10 | 2.5-9 | 2-8 |

| Speedofaxis(r/min) | 82 | 105 | 105 | 130 | 130 |

| DiaofRing(mm) | 1620 | 1270 | 1270 | 970 | 970 |

| DiaofRoller(mm) | 450 | 410 | 410 | 320 | 320 |

| Rollerheight(mm) | 250 | 210 | 190 | 180 | 160 |

| Mainmotor(KW) | Y315m-4-132 | Y280s-4-75 | Y280s-4-75 | Y225s-4-37 | Y225s-4-37 |

| Fanmotor(KW) | Y315m-4-132 | Y250m-4-75 | Y250m-4-75 | Y200L-4-37 | Y200L-4-37 |

| Analysismotor | Y160m-4-11 | Yc200-4-7.5 | Yc200-4-7.5 | Yc120-4-5.5 | Yc120-4-5.5 |

Whole production line introduction

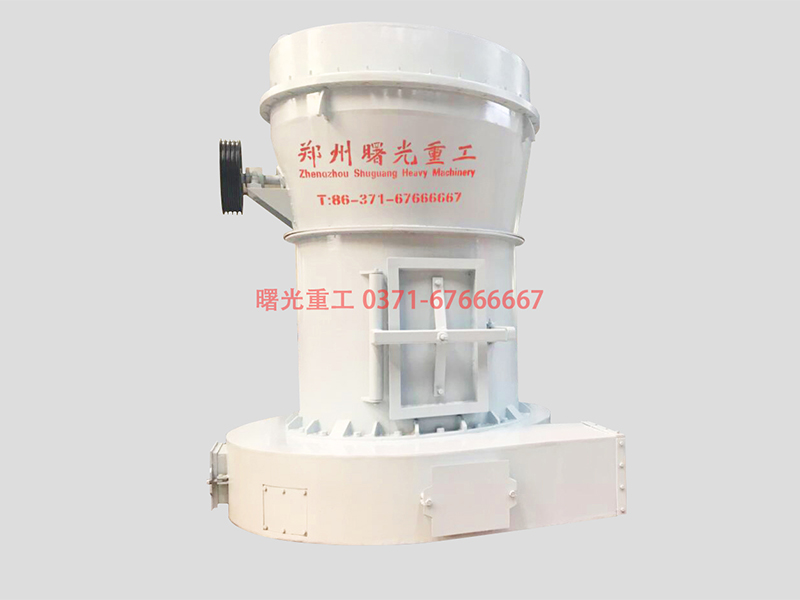

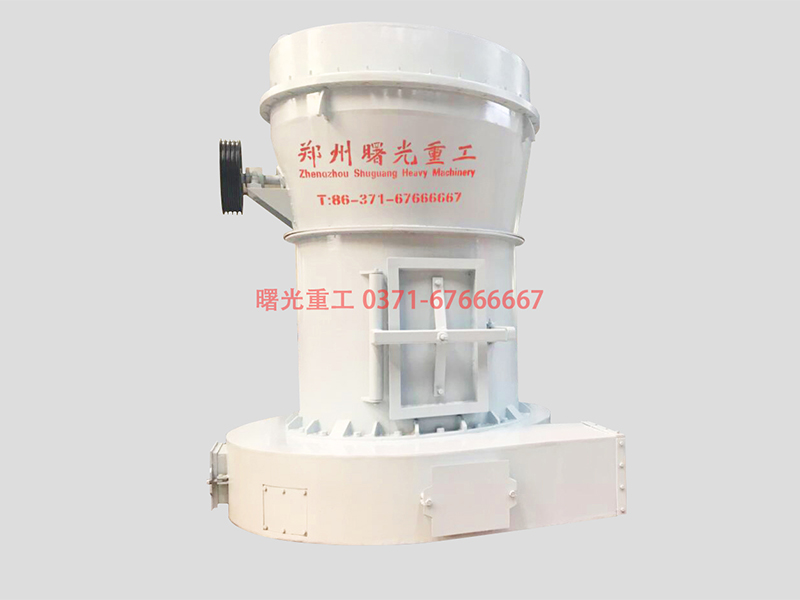

Raymond mill structure and working principle

The whole raymond mill line include main machine,powder collector,dust catcher,fan,reducer.

The inner of the main machine include axis,roller,grinding ring,shovel blade and so on.

Working Principle of Raymond Mill (Grinding Mill):

A.Raw material is crushed by jaw crusher to the size required which is suitable for the Raymond Mill (Grinding Mill) ,

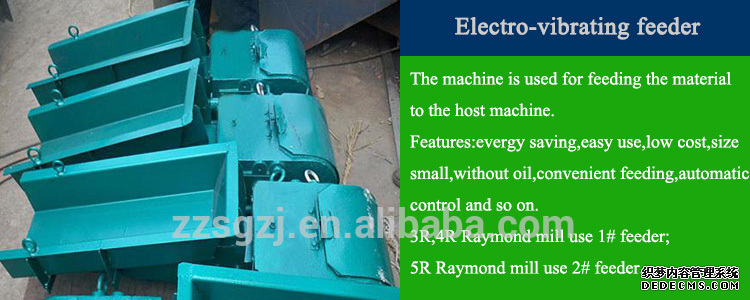

B.Then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for grinding mill. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

C.After this, the ground stuff are carried by the air from the blower into the powder separator (Analyzer Machine) for screening. The fine powers are blow into the cyclone powder collector and are poured out through the output-powder valve as the final products, and the corase stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Customer working site and visit